Why Corrosion Coating Is Essential For Heat Pumps ??

Coastal environments are notorious for their high levels of airborne salt and humidity, which pose significant risks to the longevity and performance of heat pump systems. The two primary factors air salinity and humidity which creates continuous threat to unprotected condenser coils and metal enclosures.

Coastal environments are notorious for their high levels of airborne salt and humidity, which pose significant risks to the longevity and performance of heat pump systems. The two primary factors air salinity and humidity which creates continuous threat to unprotected condenser coils and metal enclosures.

High humidity levels further intensify corrosion by accelerating electrolytic reactions on metal surfaces. Even without direct seawater contact, salt can settle onto metal components through wind. This salt attracts water vapor, forming a corrosive electrolyte layer that leads to pitting, rusting, and ultimately, structural breakdown of condenser coils and other metal parts.

PROTECT YOUR INVESTMENT

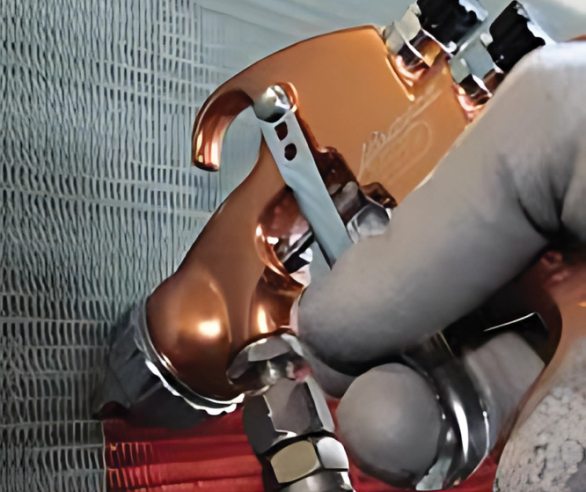

To safeguard the condenser and evaporator coils of the AQUATECH and QUANTUM range of heat pumps, Weather Makers offers a comprehensive range of corrosion resistant coatings. Additionally, the enclosure of the heat pumps can also be protected with these specialized coatings.

.png)

.png)

.png)

.png)

.png)

.png)